Stacker-reclaimers are mainly used for loading and unloading iron ore (sand), coal, sand, etc. in bulk yards of bulk cargo terminals, steel mills, large thermal power plants and mines. They have high operating efficiency and a wide range of applications. Circular stacker-reclaimers are one of the key large-scale equipment in cement plants. They can complete the stacking and mixing and reclaiming of limestone simultaneously or separately, and play a vital role in pre-homogenization of limestone, stabilizing kiln conditions and ensuring the quality of clinker.

Stacker-reclaimers have two operating modes: stacking and reclaiming. The bulk materials transported by the belt conveyor are unloaded to the belt conveyor on the boom through the tail car, and thrown from the front end of the boom to the material yard. Through the operation of the whole machine, the rotation and pitching of the boom can make the material pile form a neat shape of a trapezoidal cross-section. Reclaiming is achieved continuously by the rotation of the boom and the rotation of the bucket wheel. The material is unloaded to the reverse-running boom belt conveyor through the unloading plate, and then unloaded to the material yard belt conveyor through the funnel below the center of the machine. Through the operation of the whole machine, the rotation and pitching of the boom, the bucket wheel can take all the materials in the storage pile.

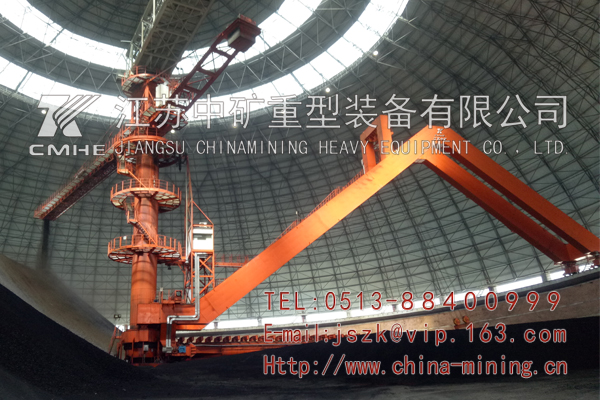

The circular stacker-reclaimer is a device that integrates stacking and reclaiming. It is placed in a circular steel structure pile shed. It uses a cantilever stacker and scraper reclaimer that can rotate along the fixed central column to perform bulk material stacking and reclaiming operations respectively.

The circular stacker-reclaimer is a device that integrates stacking and reclaiming. It is placed in a circular steel structure pile shed. The circular stacker-reclaimer is a device that integrates stacking and reclaiming. It is placed in a circular steel structure pile shed. The circular stacker-reclaimer is a device that performs homogenization, storage and transportation of raw materials. It consists of a column structure, a main beam structure, a walking structure, a material rake and a material rake trolley structure, a cantilever belt conveyor and platform railings of each part, plus transmission and other parts.

The circular stacker-reclaimer is covered by a hemispherical coal tank shell. The stacking and reclaiming operations are concentrated within the rotating range of the centering rotation and are not affected by typhoons and other severe weather conditions. At the same time, the dust generated is small and confined to a fixed area. Therefore, it solves the large-scale pollution to the surrounding environment caused by the large amount of dust generated by the operation of conventional open strip coal yard stackers. It is both beautiful and environmentally friendly, with high comprehensive benefits. It has the advantages of large coal storage capacity, small footprint, high site utilization, high safety and reliability, and good environmental benefits.