The elemental sulfur in the coal with calcium-based methods such as fixed to a solid prevent the generation of SO2 during combustion.By domestic and foreign desulfurization technology and the introduction of the domestic power industry analysis desulfurization pilot plant situation, the current desulfurization method can generally be divided into pre-combustion desulfurization, desulfurization of combustion and post-combustion desulfurization three categories.

1.After combustion desulfurization, also known as the FGD (flue gas on an, referred to as FGD), in the FGD technology, according to the category division of desulfurizer can be divided into following five ways: for calcium by MgO magnesium, using Na2SO3 as sodium, with NH3 as ammonia, the organic alkali as organic alkali method based on calcium carbonate (limestone). The common use of commercial technology in the world is the calcium method, which accounts for more than 90% of the total.

2. According to absorbent and desulfurization products in the desulfurization process of wet and dry state can be divided into wet and dry desulfurization technology, dry and semi dry (semi wet) method. Wet method FGD technology is to use a solution containing the absorbent or slurry in the condition of wet desulfurization desulfurization and processing, the method has the desulfurization reaction speed, simple equipment, high desulfurization efficiency, but the universal existence serious corrosion, operation of the high cost of maintenance and easy to cause secondary pollution, etc. Dry process desulphurization absorption of the FGD technology and product processing are conducted in the dry state, the law has no sewage waste acid discharge, equipment corrosion, to a lesser degree, no significant cooling in the process of purification, purifying flue gas after high temperature smoke, conducive to the chimney exhaust diffusion, less secondary pollution, but the desulfurization efficiency is low, reaction speed is slow, huge equipment, etc. Semi dry FGD technology refers to the desulfurization agent in the dry state desulfurization, in the wet state regeneration (such as the washing of regeneration of activated carbon process), or desulfurization in wet state, in the dry state processing desulfurization products such as spray drying method flue gas desulfurization technology. Especially in the condition of wet desulfurization, desulfurization in dry condition processing of half dry method, with both the wet desulfurization reaction speed, the advantage of high desulfurization efficiency, and have no sewage waste acid discharge, dry desulfurization after product is easy to deal with the advantage of the widespread attention by people. According to the purpose of the desulfurization, can be divided into two kinds of, abandon and recycling method.

Dry desulfurization

The process for power plant flue gas desulphurization began in the early 1980s, compared with the conventional wet scrubbing process has the following advantages: low investment cost; desulfurization product is dry state and fly ash blended; without installation of demister and reheater; equipment corrosion is not easy. It's not easy to change scaling and clogging. The disadvantage is that the availability of absorbent rate lower than the wet flue gas desulfurization process; for high sulphur coal when the economy is bad; fly ash and desulfurization products of blended may affect the comprehensive utilization of; on the drying process control requirements are very high.

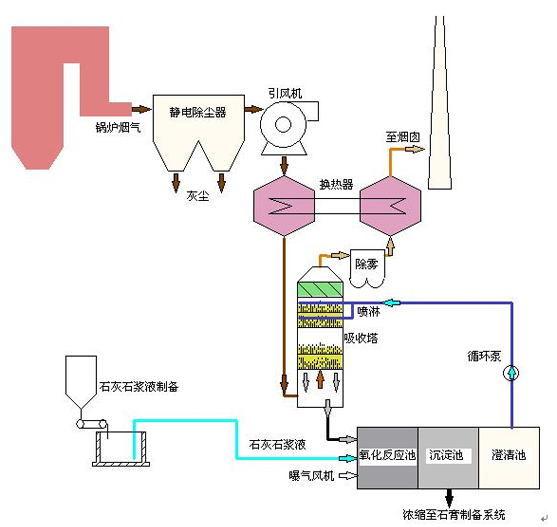

Wet process

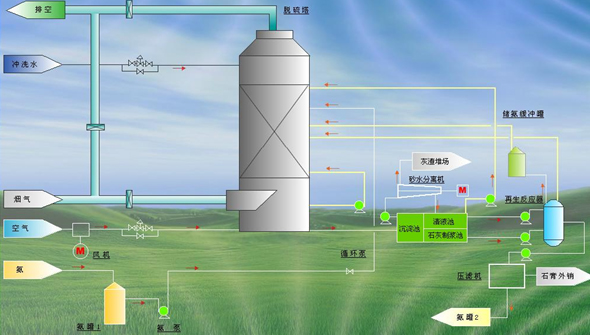

The world of wet flue gas desulfurization process, form and mechanism are similar, mainly the use of limestone (CaCO3), lime (CAO) or sodium carbonate (Na2CO3) slurry as a detergent, in the reaction tower for flue gas washing, thereby removing SO2 in flue gas. This process has 50 years of history, through continuous improvement and perfection, technology is relatively mature, but also has high desulfurization efficiency (90% ~ 98%), large capacity units, coal adaptability, low operation cost and side product is easy to recovery advantages. In large thermal power plant, more than 90% of the wet lime / limestone - gypsum flue gas desulfurization process.

Ammonia desulfurization process:

Electron beam method

When the electron beam is irradiated with the flue gas containing water vapor, it can make the molecules in the flue gas such as O2, H2O, etc. in the excited state, ion or pyrolysis, producing strong oxidizing free radicals O, OH, HO2 and O3 etc.. These free radicals in the flue gas of SO2 and NO oxidation, respectively, into SO3 and NO2 or the corresponding acid. In the presence of ammonia, to form a stable ammonium sulfate and ammonium sulfate solid, they are dust collector set down to desulfurization denitration.

Pulse method

The basic principle of pulse corona discharge desulfurization, denitration, basic principle and electron beam irradiation desulfurization denitration are basically the same, many countries in the world were a large number of experimental studies, and the trials of the larger scale, but there are still many problems to be solved.

Seawater desulfurization

Normally alkaline seawater, the natural alkalinity of about 1.2 ~ 2.5mmol / L, which makes the water has a natural pH buffer capacity and the ability to absorb SO2. Some foreign companies use this feature desulfurization seawater, developed and successfully applied seawater washing flue gas SO2, to achieve the purpose of purification of flue gas.

Seawater flue gas desulfurization process mainly by the system, the water supply and discharge system, water recovery system and other components.