Ⅰ、Application range

Air blaster ( also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) is a special device for preventing and eliminating arc camber, blocking, wall sticking and lingering of all kinds of material silos, material hoppers and pipeline forkings. It is applied in all kinds of cylinder material silo made of steel and concrete,material hoppers, pipelines and stockpile. Air blaster is widely used to store and transport bulk material in fire generating plant, coal mining and underground coal silo, coal washing plant, cement plant, concrete processing plant, casting factory, fertilizer factory, coking factory, gasworks, chemical industry factory, aluminium factory, alkali factory, steel factory, mining, wharf, foodstuff, feed factory, boiler, and pharmaceutical factory.

Ⅱ、Characters

1、High efficiency:Air cannon is designed for the places where it is easy to be arched and to pile material. It directly have effect on the material.The efficiency of cear material will be good.

2、Safety:air blaster(also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) is designed and manufactured according to the regulation of pressure vessel. As compressed air is sprayed out from the pressure vessel temporarily and the volume used every time is limited, it will not resonate and impact the silo wall and pipeline. For explosion prevention condition, it will use explosion prevention magnetic valve or pneumatic valve. It will not have an explosiive danger to the surrounding media.

3、Big capacity:air blaster (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) successfully prevent and eliminate the arc and blocking of all kinds of materials by the air flow impact force generated by the suddenly blowing out of air in the air holder.

4、Low energy consumption:As air blaster (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) works intermittently, the released compressed air is not very big and it reduces the consumption of air energy. It is lower than other blocking elemianting devices in energy consumption.

5、Lower noise:The sound of released compressed air is almost absorbed by the material in the silo. And it works intermittently.Therefore the noise is low and is without harm.

6、Complete types:KL、KT、KH etc. different structures and different control ways can be selected according to different storage silo, installation space and surrounding media.

7、Air blaster (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) is charcterized by simple structure, easy to install and dismantle, easy maintenance and proection.

Ⅲ、Work principle

Air blaster uses the strong air flow suddenly generated by the sprayed compreseed air, which directly crushes into the blockage area of storing bulk loading material. The energy generated from sudden expansion will overcome the arching or stickiness because of static friction, making material in silo restore gravity flow or making pipeline convey the material continuously to guarantee the continuous manufacture.

3、Big capacity:air blaster (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) successfully prevent and eliminate the arc and blocking of all kinds of materials by the air flow impact force generated by the suddenly blowing out of air in the air holder.

4、Low energy consumption:As air blaster (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) works intermittently, the released compressed air is not very big and it reduces the consumption of air energy. It is lower than other blocking elemianting devices in energy consumption.

5、Lower noise:The sound of released compressed air is almost absorbed by the material in the silo. And it works intermittently.Therefore the noise is low and is without harm.

6、Complete types:KL、KT、KH etc. different structures and different control ways can be selected according to different storage silo, installation space and surrounding media.

7、Air blaster (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) is charcterized by simple structure, easy to install and dismantle, easy maintenance and proection.

Ⅲ、Work principle

Air blaster uses the strong air flow suddenly generated by the sprayed compreseed air, which directly crushes into the blockage area of storing bulk loading material. The energy generated from sudden expansion will overcome the arching or stickiness because of static friction, making material in silo restore gravity flow or making pipeline convey the material continuously to guarantee the continuous manufacture.

Ⅳ.The selection and arrangement of Air blaster(also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus)

1、Familiar blocking types(refers to figure 4)

In all kinds of material silos, storage material will have different blockage types because of moisture and squeezing. Usually there is:a、arch type b、Bridge type c、funnel type。In the pipeline, there is blockage as the following:d、Storage blockage e、Partial blockage etc.

2、Normal selection principle

The selection of type KL,KT and KH are confirmed according to the installation space and convenient installation. Different model of air blaster(also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) will have different blockge effect.

De-clogging of 15L、30L、50L、75L volume are mainly used in the site where is with smaller specific gravity, better flow capacity, small storage volume and smaller section. Such as: barn, feedstuff, raw material of chemical industry, sawdust, plastic silo,small cement silo, discharge silo of cyclone seprator and bag filter, discharge silo of static precipitator and material conveying pipeline.

Air blaster of volume 100L、150L is mainly used to store common material in middle and small material silos. Such as: small material silo of fertilizer, cement, sand for casting, small loading gate, small stone silo .

The selection of type KL,KT and KH are confirmed according to the installation space and convenient installation. Different model of air blaster(also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus) will have different blockge effect.

De-clogging of 15L、30L、50L、75L volume are mainly used in the site where is with smaller specific gravity, better flow capacity, small storage volume and smaller section. Such as: barn, feedstuff, raw material of chemical industry, sawdust, plastic silo,small cement silo, discharge silo of cyclone seprator and bag filter, discharge silo of static precipitator and material conveying pipeline.

Air blaster of volume 100L、150L is mainly used to store common material in middle and small material silos. Such as: small material silo of fertilizer, cement, sand for casting, small loading gate, small stone silo .

Air cannon (also called air assistance thyristor, arch destroying apparatus, blockage delete apparatus)、500L is mainly used to store bigger specific gravity material, bigger storage volume and bigger section material silo, bad flow and easily pressed lump material silo. Such as: all kinds of coal silo, raw coal silo of bigger volume, surge bin, silos for small stone and ore and other special application conditions. of volume 300l.In heat conditon, heat resistant air blaster should be selected.

For the site of explosion prevention, hand valve, pneumatic control valve or electric control explosion prevention solenoid valve should be selected.

For the site of explosion prevention, hand valve, pneumatic control valve or electric control explosion prevention solenoid valve should be selected.

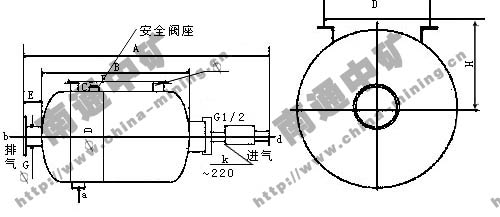

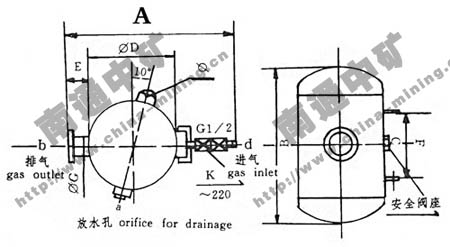

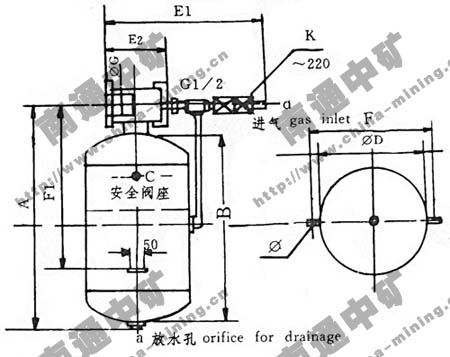

Ⅴ、Installation dimension and parameter

|

Type

|

Volume

L |

A

Mm |

B

Mm |

&D

mm |

F

Mm |

E

mm |

&G

Pipeline Mm |

D

Mm |

&Hang ring,pedestal hole

|

K air inlet hole

|

Work pressure

Mpa |

Crushing

N |

Explosive capacity

Kgfm

|

W

kg |

|

A-I

|

50

|

845

|

565

|

360

|

180

|

60

|

50

|

-

|

14

|

G1/2

|

0.4-0.8

|

1370-3720

|

6800

|

31

|

|

A-II

|

70

|

915

|

630

|

410

|

200

|

65

|

80

|

-

|

18

|

G1/2

|

0.4-0.8

|

1580-5100

|

9400

|

78

|

|

A-III

|

100

|

1220

|

900

|

410

|

-

|

100

|

80

|

300

|

18

|

G1/2

|

0.4-0.8

|

3500-8000

|

14300

|

87

|

|

A-IV

|

170

|

1220

|

900

|

510

|

-

|

100

|

102

|

300

|

18

|

G1/2

|

0.4-0.8

|

4300-9600

|

21500

|

98

|

|

Type

|

Cubic

L |

A

Mm |

B

Mm |

&D

mm |

F

Mm |

E

mm |

&G

Pipeline Mm |

D

Mm |

&Hang ring

,pedestal hole Mm |

K Inlet hole

|

Work pressure

Mpa |

Crushing force

N |

Explosive energy

Kgfm |

W

kg |

|

C-IV

|

170

|

1200

|

900

|

510

|

-

|

-

|

102

|

300

|

18

|

G1/2

|

0.4-0.8

|

4300-9600

|

21500

|

92

|

|

C-V

|

220

|

1305

|

1005

|

562

|

-

|

-

|

102

|

400

|

20

|

G1/2

|

0.4-0.8

|

4800-11000

|

36400

|

148

|

|

C-VI

|

300

|

1487

|

1187

|

612

|

-

|

-

|

102

|

500

|

20

|

G1/2

|

0.4-0.8

|

5100-11500

|

40800

|

187

|

|

C-VII

|

500

|

1721

|

1421

|

712

|

0

|

0

|

102

|

800

|

20

|

G1/2

|

0.4-0.8

|

13800-28700

|

68000

|

217

|

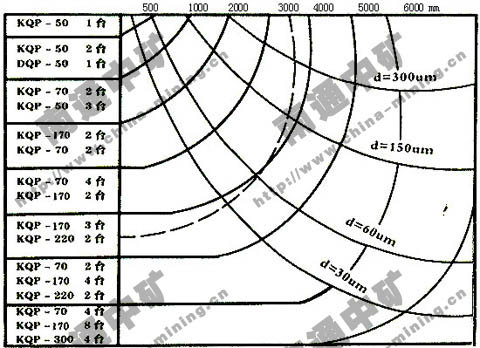

Ⅵ、Selection

In all kinds of storage material silo, stored material will have some different arch blockage because of moisture and piled ressure. To meet the request of all kinds of condition, our company have many types of specifications of air canon(also called air assistance flow utensil, destroyed arch utensil and clean blockage.) for selection. The selection and arrangement type should accord to type, volume, crossing section, discharge angle, stored materual character, environment of material silo.

1、Type selection principle:

(1) Air canon of 30、50、70Lvolume is mainly used to store small gracity, good flow ability and small stored volume site.Such as foodstuff silo, wooden meal, plastic silo,small cement silo and conveying pipeline.

(1) Air canon of 30、50、70Lvolume is mainly used to store small gracity, good flow ability and small stored volume site.Such as foodstuff silo, wooden meal, plastic silo,small cement silo and conveying pipeline.

(2) Air canon of 70、100、170L volume is mainly used to store small and middle material silo for common material. Such as:fertilizer, cement, sand for casting, small loading gate and small silo etc.

(3) Air canon of 170、300L volume is mainly used to store big gravity, small storage capacity and crossing section, bad flow condition and easyily pressed store material silo. Such as:all kinds of middle loading coal silo, big capacity raw coal silo, impact silo and small fine mining selection etc.

(4) Air canon of 500L volume (also called:air assistance flow utensil, destroyed arch utensil and clean blockage utensil),Mainly use in the bigger stored coal silo, bigger gravity fine mining and other special application. It should select air control type or electric control and explosion prevention magnetic valve.

It should select air control type or electric control magnetic valve for the site of explosion prevention.

It should select air control type or electric control magnetic valve for the site of explosion prevention.

Description:

1、Different material has different characters. He skining and blockage condition in material silo will be different. Therefore the quantity of air canon(also called air assistance flow utensil, destroyes arch utensil and clean bloakage utensil) will have many difference. Generally the material is finer,it is difficulity to block. Lump materual is different to clean when lump materal is toothed and blocked.

2、Material silo has round and square.When the shape is square, the diameter is the length of diagonal.

3、The material of material silo meet the following several conditons and will select a little biggerair canon(also called air assistance flow utensil,destroyed arch utensil and clean blockage utensil.)

(1)Higher and stronger clay material;

(1)Higher and stronger clay material;

(2)Lump material with tooth ;

(3)Concretion material for a long time storage;

(3)Concretion material for a long time storage;

(4)Cone angle of material silo is plain or small outlet;

(5)Strong absorption moisture or sensative temperature material

(5)Strong absorption moisture or sensative temperature material

Ⅶ、Installation

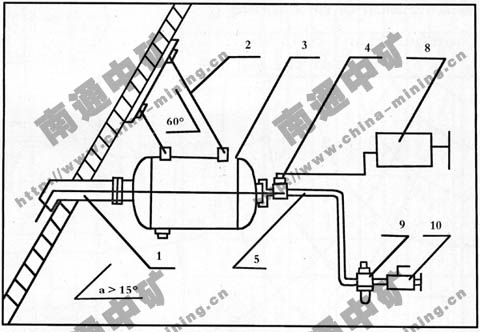

1、Air canon(also called:air assistance flow utensil, destroyed arch utensil and clean blockage utensil).In the easily blocked position of material silo, arrange pre-set hole or cut a hole at site to weld spraying pipe of air canon(or fix with the concrete) in the silo wall. Then connect air discharge pipe of air cannon with the flanges. The screw button of air buuble or steel stipe is ahnged in silo wall or other buildings(see figure 5a). Also fix in the inspection platform or silo wall to weld with frames(see fugure 5b), to ensure the stability of air bubble.

2、When installation air canon(also called air assistance flow utensil, destroyed arch utensil, clean blockge utensil),air discharge pipe should be downward. The angle to the level is not less than 15°.Spraying pipe of air canon and air outlet connection should not arrange elbow, bending pipe. Connect it in line. Spraying pipe should be shorter. The length should be not over 1.2m. When using pneumatic control, the distance between air bubble and air outlet opening should not be over 15m.

3、Two digitial and three ways magnetic valve should be instlled near air inlet pipe of air cylinder. The length of connecting two digitial and three magnetic valve and connection pipe of air cylinder should not be over 30mm. Not to arrange elblow and bending tube, avoid to have effect on the restored time of piston,at the same time, have effect on explosive energy.

4、All connection positons and pipelineof air sourcce should be no air leakage. The comppressed air for application should be filtered, cleaned,dried and keep stable pressure. The Max. work pressure is 0.8Mpa. Work pressure is higher, explosive energy will be larger. The crushing force will be bigger. When providing compressed air separately, air pressusre is higher, and the pressurre is stable, pressure loss will be smaller.The effect of cleaning blockage of Air canon (also called air assistancce flow utensil, destroyed utensil and clean blockage utensil) will be better. When compressed air is provided concentratedly, consider to install manometer. Watch the conditon of air pressure. Avoid of the loss of pipeline is too large and have effect on the work of air canon (also called air assistance flow utensil, destroyed utensil and clean blockage utensil) or reduce work efficiency. The Min. work pressure od air canon will not less than 0.4Mpa.

5、Drainage stop of air canon(also called air assitance flow utensil, destroyed arch utensil and clean blockage utensil(should be downward, it is easy to discharge water. If air bubble is off the ground or platform higher, and the moisture of sir source is too big, it may connect one section in water discharge to the convenient operation positon and install one valve. Ensure water discharge frequently. The principle of adding connection pipe must be sealed and have no any leakage.

6、Single direction valve and ball valve should be install the convient position for operation.

7、Before Air canon(aslo called air assistance flow utenil, destroyed arch utensil and clean blockage utensil) is not fixed with material silo, don’t fire a gun at random.

8、When installation air canon in heat equipment, (also called:air assistance flow utensil, destroyed archutensil, clean blockage utensil), air bubble should be away from heat equipment and environment temperature is lower than -10℃. When environment temperature is lower, make some mesurements.

9、Rated AC voltage of two digitial and three ways magnetic valve is 220V. When starting, power consumption is 22VA.

10、Usually it is used electric control, put on the power of two digitial and three ways magnetic valve and it may press the button of control. Electric control may accord to the cudtomer’s request, site control or control with control room, control in single or in many set, timing controletc.

Installation sketch is as the following: