|

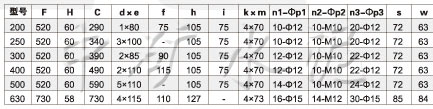

Type

item

|

B250

|

B300

|

B500

|

|

|

Valve body

|

flow

|

120

|

130

|

300

|

|

Flow speed

|

3

|

3

|

3

|

|

|

Rotating angle

|

71

|

71

|

71

|

|

|

Flow area

|

0.0113

|

0.0148

|

0.036

|

|

|

Aerating layer

|

material

|

nylon

|

nylon

|

nylon

|

|

Ventilating area

|

0.067

|

0.064

|

0.16

|

|

|

Aerating area

|

0.171

|

0.22

|

1.55

|

|

|

Suitable temperature

|

≤100℃

|

|||

|

Relative moisture

|

<1%

|

|||

|

Aerating chute

|

0.005~0.01MPa

|

|||

|

Suitable media

|

Cement raw material, cement product, powder of aluminum and magnesite, mine powder, fossilmeal

|

|||

IV Working principle

Flow control valve is mainly composed of seat, valve body, sealing valve, bushing, valve core, bearing, ventilating layer, aerating chute and driving device. The fan gives low pressure and small volume air, which will go through the pathway and aerate the chute. Air goes through the ventilating layer and blow air upward to make the material flow upward. When the material falls down, the inclination of the equipment will help the material move forward continuously. The actuator will drive the coupling and valve core to adjust the material flow. The rotary vale just works as switch to give order to the handspike by means of solenoid valve controlling pneumatic handspike source and finish the whole shifting.